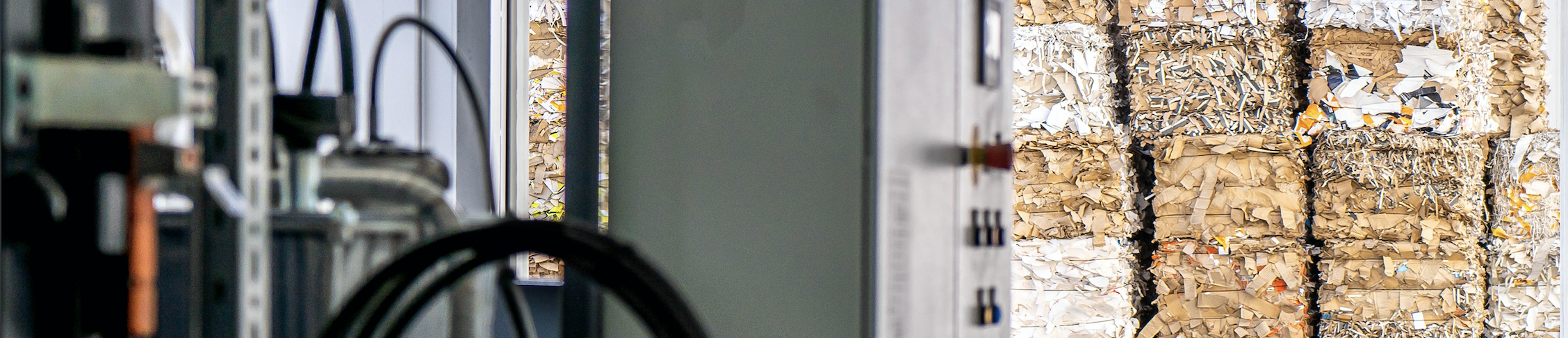

Cardboard Balers

JM Mechanical Services offers 24 hours, 7 days a week, complete Cardboard Baler repair and maintenance services on all major brands of waste management equipment. We are available for on-site visits to your premises and troubleshooting. JM Mechanical Services also provide a breakdown service to assist with any issues related to maintenance or performance. We offer scheduled maintenance programs that will keep your equipment running like new and catch the small issues before they grow and become catastrophic. Our aim is to keep your waste management systems running at the highest capacity possible.

General Enquiries

Email: info@jmservice.co.nz

Phone: 0800 566 324

We specialize in:

- Preventative Maintenance

- Cardboard Baler repairs

- Cardboard Baler parts

- Card board Baler maintenance and service programs

- Cardboard Preventative maintenance

JM Mechanical Services has access to most brands of spare parts for Compactors and Balers. If you are after a new Compactor or Baler that can be arranged, or alternatively we can give you advice on products to find what is the most suitable for your needs.

Contact us today if you need service, repairs, or a new Cardboard baler on ☏ 0800 566 324

FREQUENTLY ASKED QUESTIONS

What are the different types of baler machines?

There are two types of baler machines: vertical and horizontal. Each type comes with different specifications, from their load capacity to their pressing power. However, horizontal balers tend to be bigger and are for heavy duty use. Vertical and horizontal balers can crush cardboard, plastic, timber and even tyres.

Which type of baler is better for me?

This depends on how much waste produce and how much baling you need to do. Small to medium business can do with a vertical baler producing 70kg to 200kg bales, although we do have vertical balers that can produce 1000kg bales. Horizontal balers cater for clients who produce large amounts of waste and need industrial waste management solutions.

What can be fed to the baler machine?

Made for commercial and industrial applications, these horizontal baler machines can effectively process anything, from general waste to food waste to dry recyclables. How does a horizontal baler machine work?

Rubbish is fed into a hopper that is located at the top of the machine. The waste is then fed onto a conveyor system which brings it toward the hydraulic presser. Once the hopper is full, the machine is switched on and compresses the waste into a bale. This is then tied with heavy duty wires before being ejected from the machine.

Do I need to invest in a horizontal baler machine?

The horizontal baler machines we have for sale are ideal for improving waste management. By compressing large amounts of waste into manageable bales, you can better manage your space and your expenses. Strong ROI is achieved through better storage capacity, improved processing and logistics and reduced manual labour.